BASF Debinding & Sintering Service – Ultrafuse 316L (1KG)

Price on request Contact us now

Availability on request

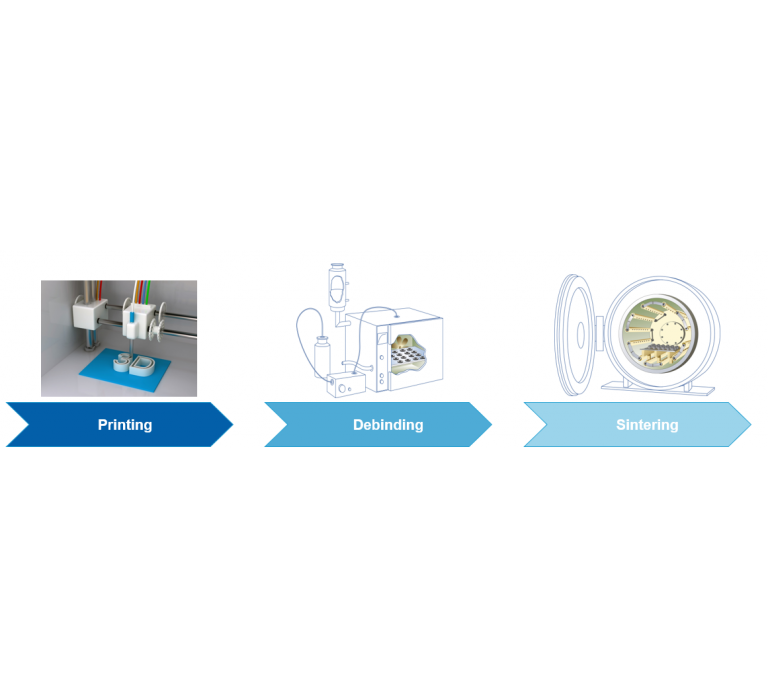

BASF Debinding & Sintering Service is a special service option for post-processing your metal-printed model from Ultrafuse 316L metal filament.

- Service in Cooperation with Elnik Systems

- Post-Processing Green Printed Parts to Full Metal Parts

- For BASF Ultrafuse 316L Filament

| SKU | 99415 |

|---|---|

| Brand | Elnik Systems |

Product description

Debinding & Sintering Service for BASF Ultrafuse 316L filament takes place in cooperation with Elnik Systems and is designed for post-processing your green parts from Ultrafuse 316L to full metal parts.

The component should be prepared for the debinding and sintering process right from the construction stage. For this purpose, manufacture your components according to the official design guidelines. After the green part has been finished, it can already be post-processed. Remove any excess artifacts, lumps, or adhesive residue and smooth the surfaces with sandpaper to achieve an even finish and to compensate for small warping errors.

The green part MUST be freed from any foreign material before the debinding and sintering process. Please make sure that there are no adhesive residues, oils, or other materials on the component. Foreign materials lead to a failed debinding and sintering process.

- service with cooperation with Elnik Systems

- post-processing your green parts to fully metal objects

- for BASF Ultrafuse 316L Filament

Note

- for further information on the construction, the official design guidelines, or the post-processing of green parts, please contact our support team

Warranty

- Please visit Terms and Conditions page

- If you have any questions do not hesitate to contact us

Product specifications

| Brand | Elnik Systems |

|---|---|

| Product State | New |

| External stock | Availability on request |

| Country Of Origin | Germany |

| Product application | Industrial, Medical, Prototyping |

| Accessory Types | Others |

Product downloads

| User Manual |